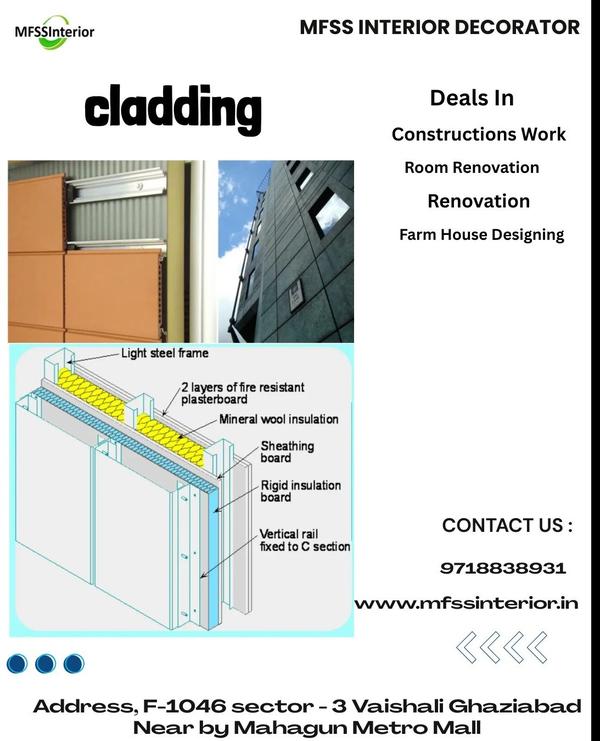

Aluminium Window And Position Work In Vaishali Ghaziabad

Got it 👍 — you’re asking about Aluminium Window and Position Work (which is typically part of both construction and renovation projects). This usually refers to the installation, fixing, alignment, and finishing of aluminium windows in buildings (offices, resorts, homes, etc.). Here’s a detailed breakdown: 🪟 Aluminium Window Work 1. Planning & Preparation Design selection – sliding, casement, fixed, top-hung, or custom. Measurements – accurate site measurement of window openings. Material selection – aluminium profile thickness (usually 1.2mm–2.0mm), glass type (clear, tinted, laminated, double-glazed). Position marking – layout marking on site (using level thread lines or laser level). 2. Fabrication Cut aluminium profiles as per design. Join corners using cleats or mechanical fasteners. Fix necessary accessories (handles, locks, rollers, hinges). Insert and seal glass with rubber beading or silicone. 3. Installation / Positioning Work Frame fixing Place window frame into opening. Align vertically and horizontally using plumb line/laser. Fix with anchor fasteners, screws, or brackets. Maintain even spacing around frame (gap for sealant). Shimming & Alignment Use shims/spacers to ensure correct position and avoid distortion. Check squareness of frame with measuring tape diagonally. Sealing & Finishing Fill gaps with PU foam or mortar. Apply silicone sealant for waterproofing. Fix beading for glass support. Install mosquito net frames (if required). 4. Quality Checks Smooth sliding/opening without friction. Proper locking/alignment of shutters. No water leakage during rain test. Airtight seal for noise and dust protection. Finishing should match wall/paint line. ✅ Tools & Materials Commonly Used Aluminium profiles & cleats Glass panels Rubber gaskets, EPDM beading Screws, anchor fasteners, brackets Drill machine, rivet gun, level, measuring tape Silicone sealant & PU foam

Subscribe for latest offers & updates

We hate spam too.